This product originated from a Shawnee State University professor who had an idea inspired by motion capture. In the beginning, our customer built several inertial sensors and sold them to various industries. Ex. : Robotics, Motion Capture, Positioning and Stabilization, Health Care Monitoring, etc.

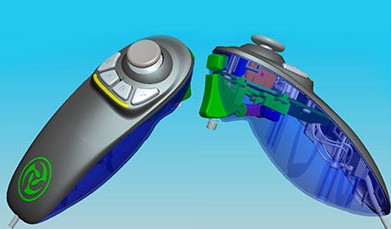

With VR products booming, our customer discovered that there weren't any ways to truly immerse users into virtual worlds using natural full-body interaction. Then he came up with the idea of putting his sensors and simulation products on key points of the human body. This captures users' movements and translates them on-screen in real time.

Our customer set up a team to launch the project, but they lacked engineering support to make the project become a reality. They needed a reliable manufacturer with a strong engineering team to help them bring their design to life. This customer seeked Kenvox out at CES. They were able to see samples of similar products and found we had the capability to manufacture their product. This interested the customer enough to visit Kenvox in China to select a supplier.

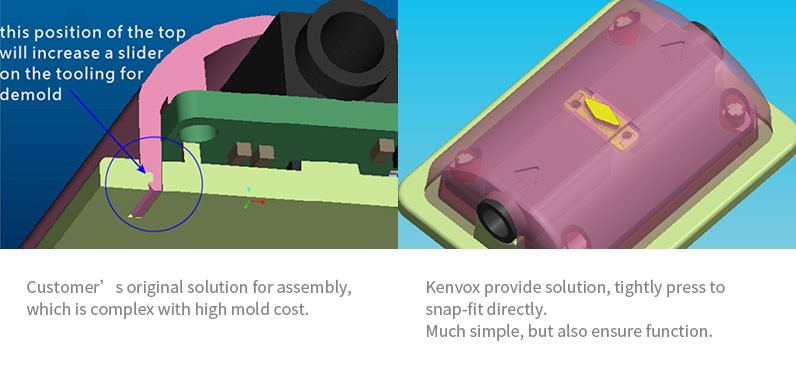

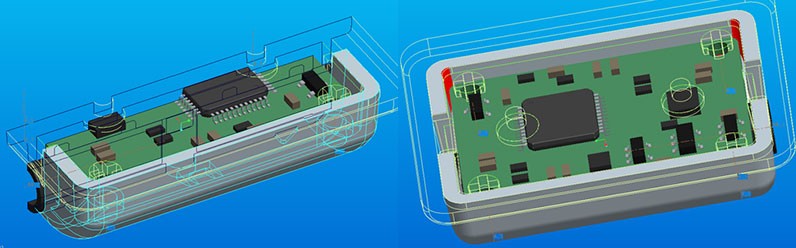

The client came to visit Kenvox and 8 other factories in Shenzen, Dongguan and Zhejian, China. After careful comparison, they decided to go with Kenvox. Even though the price was not the lowest, they liked that Kenvox was able to offer suggestions on improving assembly and cost for their customers. Our detailed analysis, professionalism and advanced facilities impressed the client. We were able to help our customer finalize the mechanical design, build a test prototype and develop the product successfully.